Cable is perfectly suited to many different mechanical applications because it is strong, it can be woven together in fine or dense strands, and it can easily have attachments like hooks and latches added to it. A sleeve can also be made to cover the mechanical cable to protect it from corrosion during use. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

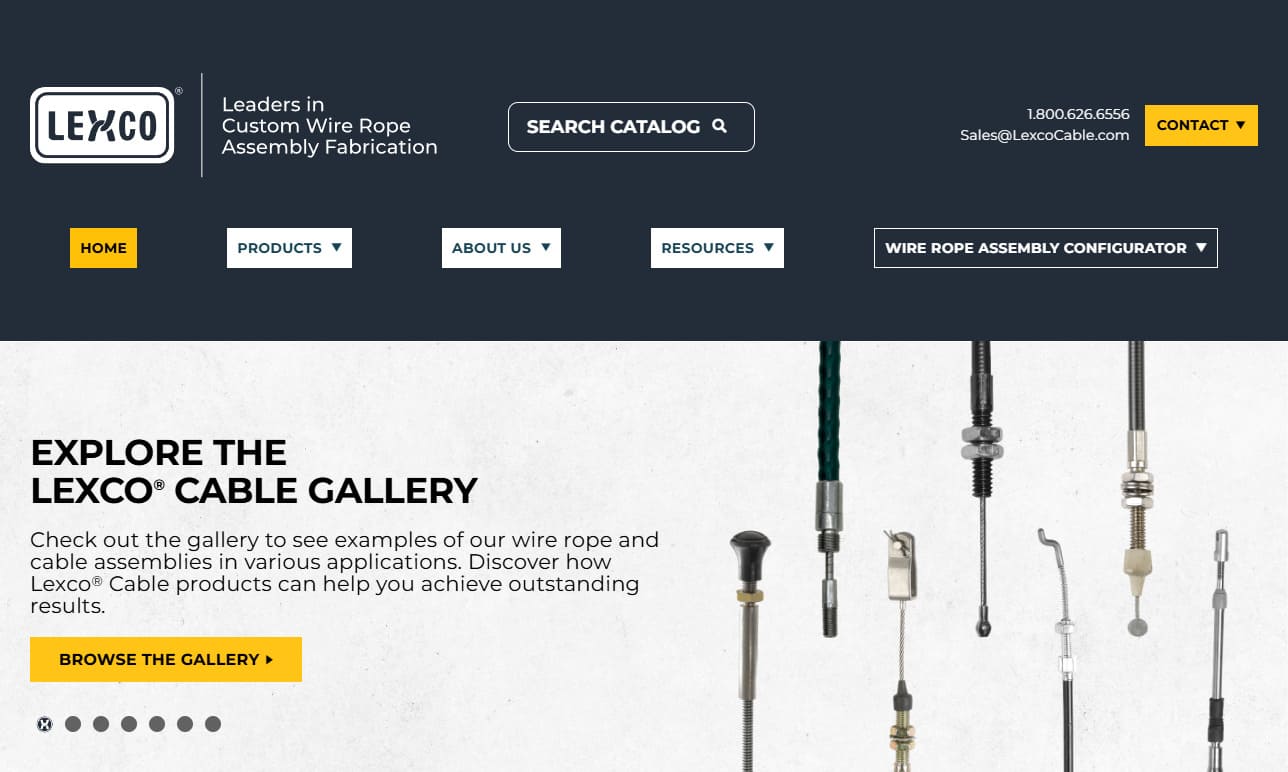

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Mechanical Cable Assembly Manufacturers

After strands of cable have been woven tightly together to create a cable that is thick enough to withstand the force that will be applied to it in a certain application, any parts that need to be added to the cable before it is installed will be added. Since mechanical cable is almost always used in an application where it will be moving, a coating is added to the finished cable to protect the metal and make the cable smoother.

Mechanical cable assemblies end up being used in medical devices, electronics, telecommunications, the aerospace industry, industrial equipment, and numerous other consumer goods.

If the cable is being manufactured and then sold to a product manufacturer, it is created in lengths that are rolled up for easy transportation and storage. Once the cable needs to be fitted, it can easily be unrolled and cut to the appropriate length.

Mechanical cables are all classified by grade and type of construction. These grades are based on the cable's overall tensile strength and resistance to abrasion. The grade of a cable determines what applications it is suitable for, and a higher grade should be used for any setting where there could be safety concerns.

In the aerospace industry, manufacturers are required to use aircraft grade cable that meets a certain minimum for tensile strength, lubrication, and packaging. The stakes are very high in airplane manufacturing, so even something as small as a minor mechanical cable needs to be durable.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services