Plastic coated cables and wire ropes are popular in a number of industries as they offer increased protection and improved aesthetics over traditional metal cables as they are available in a number of colors and textures. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

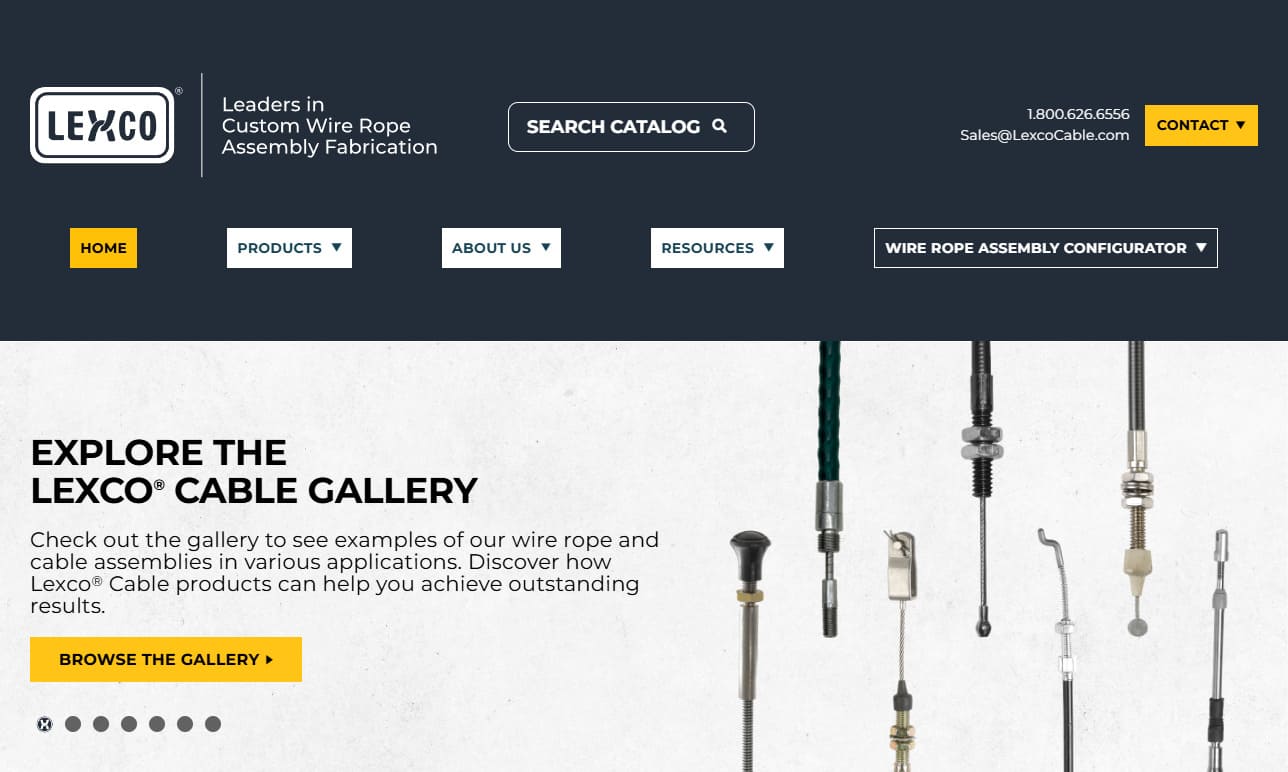

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Plastic Coated Cable Manufacturers

Though not often used in the heavy lifting and hoisting operations for which wire ropes are most commonly known, plastic coated cables are optimal for consumer goods and applications in which increased abrasion and corrosion resistance and cost-effectiveness are desired.

Though the work is often less strenuous the goal of easier lifting and hoisting is still applicable to plastic coated cables which also afford increased durability. Fitness industries use plastic coated cable in most weight machines; theater industries use black powder coated cables for stage rigging; outdoor playground equipment often use plastic coated cables, and many types of electronic equipment, communications devices, and medical devices use miniature wire rope and wire rope fittings.

Plastic jackets are also used when complete adherence to the wire or cable is not necessary. Casings made of non-plastics may be coated in plastics for added water resistance, visual appeal, etc.

In all applications, the construction of both the wire cable and the coating itself should be carefully considered to avoid mechanical failure or ill-performance.

Cables coated in plastic begin construction in much the same way as non-coated wire ropes.

There are three basic components: metal wire filaments, strands, and cores. Filaments, cold drawn metal rods of relatively small diameter, are twisted or braided to form strands. These strands may consist of two or several dozen filaments and are wrapped in a helical pattern around a core which may be metal, fiber, or polymer based.

In addition to identifications based on all materials used, plastic coated stranded wires are identified by both the number of strands per cable and the number of filaments per strand respectively. Further considerations include overall diameter, difficulty of flattening, temperature resistance, average lifespan, and material construction.

The wires themselves are often fabricated from steel, stainless steel or galvanized steel, and then coated in either nylon or vinyl (PVC), although polyethylene coatings are applied for electrical insulation and polypropylene coating is used when chemical resistance is required.

Vinyl coating is the most common since it is by far the most cost-effective; although vinyl coated cables do not have optimal abrasion and fatigue resistance, they have better flexibility and UV light resistance than nylon coated cables.

Nylon cables have excellent impact, abrasion, wear, and acid resistance, although the nylon coating degrades quickly under UV light.

Material choice is largely determined by the intended use for a cable. The rope can be coated at any stage of construction, whether individually coated filaments or an assembled cable.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services