Wire rope slings are purpose-built assemblies of wire ropes used for hoist lifting and crane rigging. These are typically constructed using steel wire ropes with end terminations. Many wire strands are twisted and braided together to create wire rope with a spiral pattern. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Wire Rope Sling Manufacturers

Comprehensive Guide to Wire Rope Slings: Construction, Types, Applications, and Selection

Wire rope slings are critical components in the lifting and rigging industry, engineered for strength, flexibility, and durability. Their unique design—comprised of bundled wires, twisted strands, and robust cores—delivers superior load-bearing capacity and resilience, making them indispensable across construction, manufacturing, marine, mining, oil & gas, and heavy transport sectors. Whether you are looking to select the right wire rope sling for overhead lifting, seeking to understand the technical make-up of wire rope assemblies, or evaluating manufacturers, this in-depth guide covers everything you need to know about wire rope slings, their advantages, and how to choose the best option for your project requirements.

Why do professionals choose wire rope slings for lifting and rigging? The answer lies in their exceptional strength-to-weight ratio, resistance to abrasion and fatigue, and adaptability to a wide range of load types, from fragile equipment to heavy structural steel. Read on to learn how wire rope slings are constructed, the types available, common industry applications, and what factors to consider when sourcing high-quality wire rope slings from reputable manufacturers or suppliers.

How Are Wire Rope Slings Constructed?

Wire rope slings are fabricated by twisting together multiple wires to form strands, which are then helically laid around a central core. This intricate construction process gives wire rope slings their impressive mechanical properties, such as tensile strength, flexibility, ductility, and the ability to absorb shock and endure repeated bending. Coatings and lubrication are often applied to minimize corrosion and enhance longevity, making wire rope slings suitable for both indoor and harsh outdoor environments.

Are you wondering what makes wire rope slings the preferred choice for heavy-duty lifting and rigging operations? Explore the detailed anatomy below to understand the physical components and design options that drive their performance.

Parts of the Wire Rope Sling

The superior performance of wire rope slings stems from their specialized construction, which includes three fundamental elements. Understanding these components is essential when specifying slings for lifting, hoisting, towing, or rigging:

1. Wires

The smallest building block of a wire rope is the individual wire, typically manufactured from high-tensile steel, stainless steel, galvanized steel, bronze, or iron. The material selection impacts the sling’s overall strength, corrosion resistance, flexibility, and suitability for specific operating conditions. For example, stainless steel wires offer enhanced resistance to rust and are ideal for marine or chemical environments, while high-carbon steel wires provide maximum strength for heavy-duty industrial lifting applications.

2. Strands

Strands are created by twisting two or more wires together in a precise pattern. The arrangement and number of wires per strand influence the sling’s flexibility and abrasion resistance. Stranded configurations help distribute the load evenly and mitigate the risk of catastrophic failure by enabling the sling to maintain integrity even if some wires become damaged during use. Common strand patterns include 6x19 and 6x37, indicating six strands with 19 or 37 wires each.

3. Core

The core forms the backbone of the wire rope sling, supporting the strands and maintaining the rope’s shape under load. Cores can be composed of:

- Fiber Core (FC): Constructed from natural (such as sisal or manila) or synthetic fibers (like polypropylene), offering greater flexibility but less resistance to crushing and heat.

- Independent Wire Rope Core (IWRC): Made from a smaller wire rope, this design delivers superior strength, resistance to crushing, and enhanced heat tolerance, making it the preferred choice for most lifting slings.

- Wire Strand Core (WSC): A single wire strand, providing a balance between flexibility and strength, typically used in light-duty applications.

Choosing the right core type is essential for meeting performance criteria such as strength, flexibility, and environmental resistance. Not sure whether you need IWRC or FC for your lifting application? Contact a wire rope expert for guidance on core selection.

Wire Rope Sling Common Strand Patterns

The strand pattern of a wire rope sling directly affects its mechanical attributes, including strength, flexibility, fatigue resistance, and ability to withstand abrasion. Different strand patterns are engineered to suit various use cases, load types, and working environments. Below are the most prevalent wire rope strand patterns, each designed to optimize performance for specific applications:

Single Layer

This basic design features a single layer of wires of equal diameter helically wrapped around a core. The typical configuration is six strands around the core, resulting in a seven-part construction. Single-layer patterns offer simplicity and ease of inspection, making them suitable for general lifting, hoisting, and light rigging tasks.

Filler Wires

The filler wire pattern comprises two concentric layers of wires surrounding the core. The inner layer typically has six wires, while the outer layer contains twelve wires of equal diameter. Six smaller-diameter "filler" wires occupy the spaces between the two layers, enhancing flexibility and fatigue resistance. This design is commonly selected for applications requiring frequent bending, such as in overhead cranes and winch lines.

Seale

The Seale strand pattern utilizes two layers of wires over the core, with the inner layer wires of smaller diameter and the outer layer wires larger and fewer in number. This arrangement places the thicker wires on the outside, enhancing resistance to abrasion and external wear. Seale patterns are ideal for slings subjected to harsh environments and heavy surface contact, such as construction or dredging.

Warrington

The Warrington pattern is a two-layer construction, where the inner layer has wires of uniform diameter and the outer layer alternates between thicker and thinner wires. The larger outer wires rest in the "valleys" of the inner layer, while the smaller wires sit on the "peaks," resulting in excellent flexibility and durability. Warrington strand patterns are often used for wire rope slings in marine, logging, and industrial rigging scenarios, where bending and wear resistance are critical.

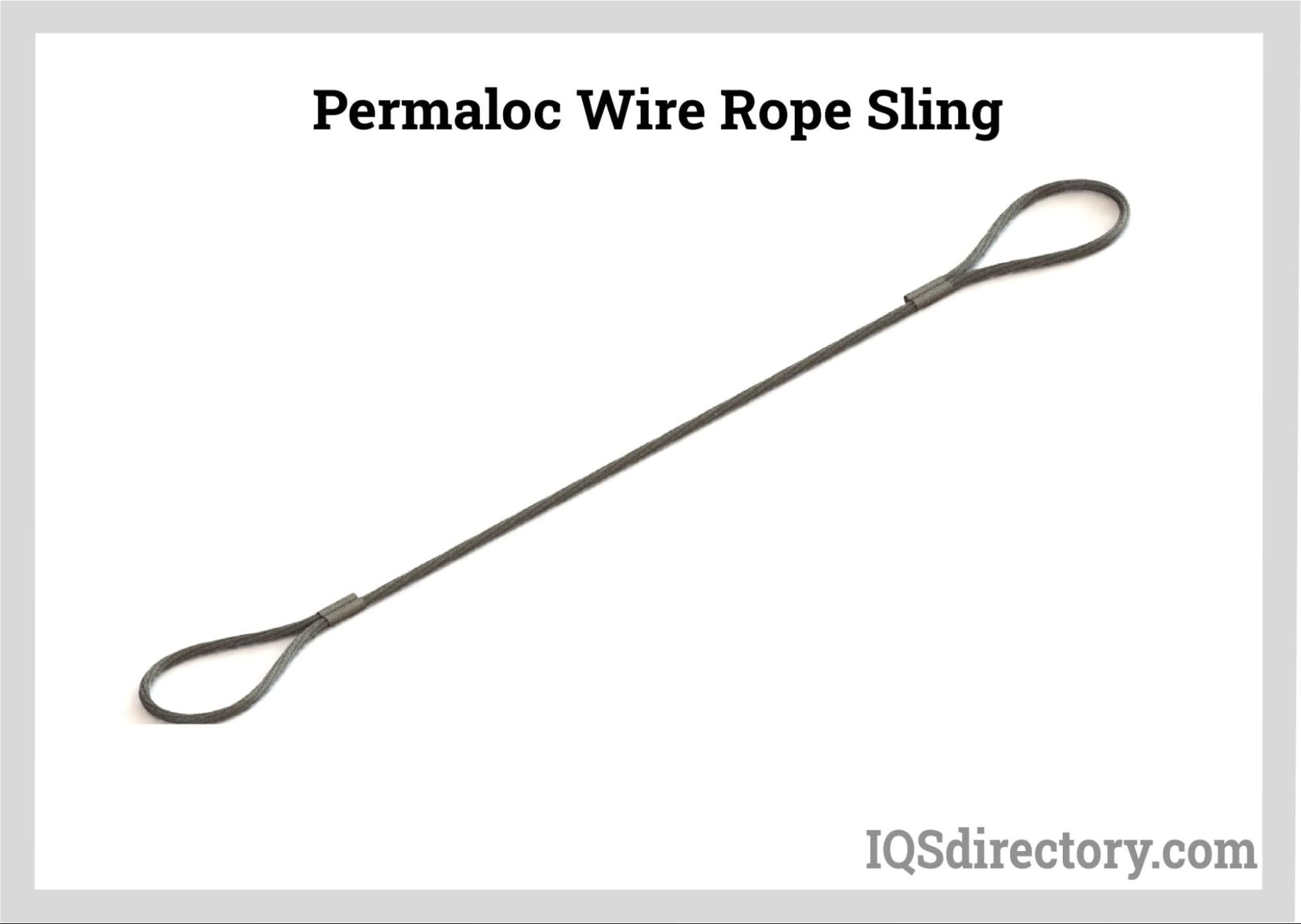

Permaloc™ Wire Rope Slings

Permaloc™ wire rope slings employ the Flemish splice method to create reinforced eyes, providing extra reserve strength. Unlike simple return loop slings, Permaloc™ designs do not rely solely on the pressed steel sleeve for load capacity, offering a safety margin if the sleeve is damaged during use. These slings are often specified for critical lifts in demanding environments where safety and durability are paramount.

- Promotes safety: Enhanced reserve strength provides additional protection during operation.

- Reserve Strength: Eyes remain intact even if the steel sleeves are compromised.

- IWRC resists crushing: Independent wire rope cores are less susceptible to deformation than fiber cores.

- Cost-effective: Reduced maintenance and longer service life save money over time.

Hidden Tuck (Hand-Spliced) Wire Rope Slings

Hand-spliced, or hidden tuck, wire rope slings are crafted by forming an eye and tucking the rope’s tail back into the sling body. This traditional technique produces a robust, snag-resistant sling without external sleeves that might catch on loads or lifting equipment. Hidden tuck slings are invaluable for lifts where pressed sleeves could get trapped, such as in confined spaces or when using choker hitches. They are also preferred for applications where minimizing protrusions is essential for safety and efficiency.

- Enhanced safety: Hidden tucks prevent snags and reduce risk of injury.

- Sleeveless design: Eliminates steel sleeves that could catch or be damaged.

- Ideal for choker hitches: Flexible and secure for tight, repetitive lifts.

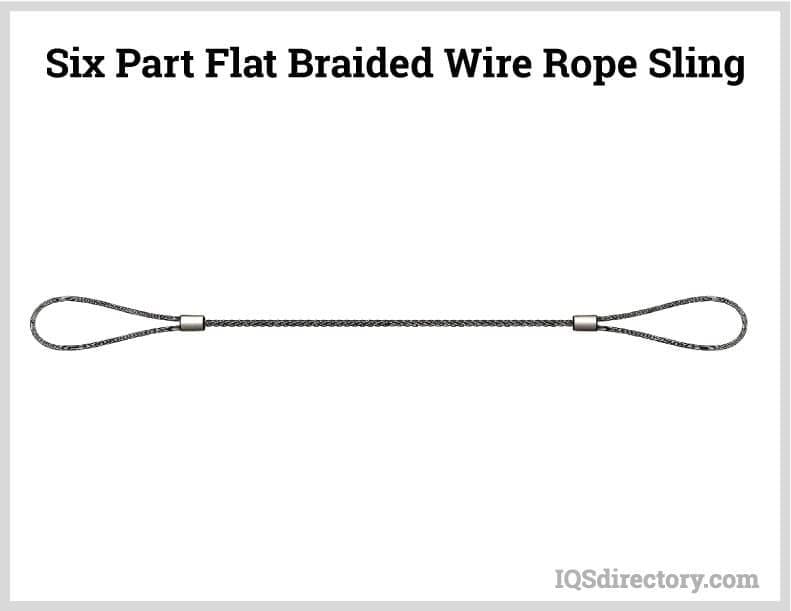

Multi-Part Braided Slings

Multi-part braided slings are constructed by braiding three to nine separate wire ropes, resulting in a flexible, high-capacity sling. The braided structure distributes the load evenly and provides excellent resistance to rotation, making these slings suitable for lifting large, heavy, or awkwardly shaped loads. The increased flexibility also allows the sling to conform closely to the load, ensuring a secure grip and reducing the risk of slippage.

- Superior flexibility: Easily adapts to the shape of the load compared to single-part slings.

- Load friction: Braided design creates friction to prevent load rotation and shifting.

- Customizable: Available in multiple configurations to match specific lifting requirements.

Key Benefits and Applications of Wire Rope Slings

Wire rope slings are renowned for their versatility, durability, and superior load-handling characteristics. They are widely specified in industries such as construction, oil & gas, marine, mining, transportation, and utilities for lifting, rigging, towing, and anchoring applications. Here are some primary advantages of using wire rope slings:

- High strength-to-weight ratio: Enables the lifting of heavy loads with relatively lightweight equipment.

- Flexibility: Can be bent, looped, or formed around loads of various shapes and sizes.

- Durability: Resistant to abrasion, corrosion (with appropriate material), and fatigue from repeated use.

- Temperature tolerance: Performs reliably in extreme hot or cold environments.

- Cost-effectiveness: Long service life reduces replacement frequency and maintenance costs.

- Safety: Multiple wire construction provides redundancy, reducing risk of sudden failure.

Typical Industry Applications

- Construction: Lifting and positioning steel beams, precast concrete, and heavy equipment.

- Oil & Gas: Hoisting drill pipes, casing, and offshore platform modules.

- Marine & Shipping: Cargo handling, mooring, and towing operations.

- Mining: Moving ore skips, draglines, and conveyor systems.

- Utilities & Power Generation: Erecting transmission towers and handling large transformers.

- Manufacturing: Assembly line lifting, die handling, and material movement.

- Transportation: Securing and lifting heavy vehicles or oversized freight.

Are you searching for the ideal wire rope sling for a specific industry or application? Discover more about tailored sling solutions for your sector.

How to Select the Right Wire Rope Sling

Selecting the most appropriate wire rope sling involves evaluating several critical factors to ensure safety, efficiency, and compliance with industry standards. Here’s a step-by-step approach to guide you through the decision-making process:

- Determine Load Requirements: Assess the weight, shape, and type of load to be lifted. Calculate the required Working Load Limit (WLL) and consider dynamic factors such as shock loading or off-center lifts.

- Choose the Sling Configuration: Decide between single-leg, multi-leg (2, 3, or 4-leg), or adjustable slings based on load stability and attachment points.

- Select Material and Construction: Consider environmental factors (corrosion, temperature) and specify the appropriate wire material and strand pattern.

- Evaluate End Fittings: Options include thimbles, hooks, master links, and shackles. Ensure compatibility with lifting equipment and load attachment points.

- Compliance and Certification: Verify that the sling meets OSHA, ASME B30.9, and other relevant regulatory standards. Request documentation as needed.

- Inspection and Maintenance: Plan for regular inspection intervals, and ensure personnel are trained to identify wear, damage, and rejection criteria.

Need help choosing the right sling for your project? Request a quote or consultation from a certified wire rope sling supplier.

Choosing the Proper Wire Rope Slings Manufacturer

When sourcing wire rope slings, partnering with a reputable and experienced manufacturer is essential for safety, performance, and cost-effectiveness. Here are actionable steps to help you identify the best supplier for your needs:

- Compare Multiple Suppliers: Evaluate at least four wire rope sling manufacturers to compare product quality, certifications, lead times, and customer service.

- Review Capabilities: Visit each manufacturer’s profile to assess their areas of expertise, production capacity, and range of sling types offered.

- Request Detailed Quotes: Use RFQ forms to request pricing, lead times, and technical specifications for your application.

- Verify Certifications: Confirm that the supplier provides slings compliant with OSHA, ASME, and industry-specific standards.

- Read Customer Reviews: Gather feedback from previous customers regarding product performance, reliability, and support.

- Ask About Customization: If you need custom-length slings, unique end fittings, or specialized coatings, ensure the manufacturer offers these services.

Each wire rope sling company typically maintains a business profile page highlighting their experience and capabilities. Use integrated contact forms to communicate directly with manufacturers for more information or to request a custom quote. For a streamlined experience, review each company’s website using available preview tools and use RFQ forms to contact multiple suppliers simultaneously.

Frequently Asked Questions About Wire Rope Slings

What are the main safety standards for wire rope slings?

Wire rope slings must comply with OSHA, ASME B30.9, and other applicable industry standards. Always request documentation and ensure your supplier provides slings that meet or exceed these regulations.

How often should wire rope slings be inspected?

Wire rope slings should be visually inspected before each use and undergo formal periodic inspection by a qualified person, according to OSHA guidelines and manufacturer recommendations. Replace slings that show excessive wear, broken wires, kinks, or corrosion.

What lifting configurations are possible with wire rope slings?

Common lifting configurations include vertical, choker, and basket hitches. Multi-leg assemblies (2, 3, or 4-leg) can be used for lifting large or unbalanced loads. Consult a rigging specialist to determine the best configuration for your application.

Can wire rope slings be repaired?

Repairing wire rope slings is generally not recommended due to safety concerns. Slings with damage, deformation, or broken wires should be removed from service and replaced by new, certified slings.

What is the difference between IWRC and FC slings?

IWRC (Independent Wire Rope Core) slings offer superior strength and resistance to crushing and heat, ideal for heavy-duty lifting. FC (Fiber Core) slings provide greater flexibility but are less robust in demanding environments.

Still have questions? Contact a wire rope sling expert for personalized advice.

Conclusion: Optimize Safety and Performance With the Right Wire Rope Sling

Wire rope slings are the backbone of safe, efficient lifting and rigging operations across a multitude of industries. Their advanced construction, customizable configurations, and inherent strength make them the preferred choice for professionals seeking reliability and value. By understanding the components, strand patterns, benefits, and selection criteria outlined above, you can confidently specify the most suitable wire rope sling for your unique application.

Ready to purchase high-quality wire rope slings or need expert guidance for your project? Request a quote or explore our curated list of wire rope sling manufacturers and suppliers to ensure your next lift is safe, compliant, and cost-effective.

Looking for more in-depth resources? Explore related topics on lifting slings, rigging hardware, and wire rope accessories to optimize your material handling and lifting operations.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services