Aircraft cables are stranded wires that are used in a wide variety of applications on or around aircraft. For example, they are used as harnesses for electrical wiring, tie-downs, stabilizers, safety fasteners, and many other purposes. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Aircraft Cable Manufacturers

Aircraft Cables: Complete Guide to Types, Applications, Maintenance, and Sourcing

Aircraft cables, also known as aviation cables or airplane cables, are specialized high-strength, flexible stranded wire ropes engineered for use in aviation and a wide range of other industries. Beyond their critical role in flight control systems, these robust cables are commonly used as wire rope slings to lift jet engines, wings, and heavy aircraft components during assembly, maintenance, and repair. Their unique combination of strength, flexibility, and corrosion resistance also makes them ideal for use as arresting gear, where they safely decelerate aircraft by engaging the tail hook and transferring kinetic energy, especially on aircraft carriers and short landing strips.

While the most visible applications of aircraft cables are in aerospace and aviation, their versatility allows them to excel in numerous other demanding environments. Industries such as agriculture, marine, construction, mining, and irrigation rely on aircraft cables for their remarkable tensile strength, fatigue resistance, and compact diameters. These properties also make them indispensable in military, defense, and high-performance industrial settings. If you’re looking to buy aircraft cable or research its uses, this comprehensive resource will guide you through types, features, maintenance, and how to select the best supplier for your needs.

What Are Aircraft Cables?

Aircraft cables are flexible wire ropes comprised of multiple high-strength steel or stainless steel wires twisted or stranded together. The most common construction is 7x7 (seven strands of seven wires) or 7x19 (seven strands of nineteen wires), providing excellent flexibility and robust load-bearing capacity while maintaining a relatively small diameter. These cables are engineered to meet rigorous safety and performance standards, such as those set by the Federal Aviation Administration (FAA), the military (MIL-DTL-83420), and various aerospace authorities.

Key Features and Benefits of Aircraft Cables

- High tensile strength: Withstand significant loads without stretching or breaking.

- Corrosion resistance: Stainless steel and galvanized options protect against rust, moisture, and harsh chemicals.

- Flexible and compact: Small diameters and flexible construction allow routing around pulleys and through tight spaces.

- Fatigue resistance: Designed to endure repeated bending and vibration without fraying or failure.

- Versatile applications: Suitable for aircraft controls, mechanical linkages, safety cables, rigging, and industrial lifting.

Common Aircraft Cable Specifications

- Available diameters: From 3/64" up to 3/8" (and beyond for specialized applications)

- Material grades: 302, 304, and 316 stainless steel; galvanized carbon steel

- Standard constructions: 7x7, 7x19, and custom configurations

- Breaking strengths: Vary by diameter and construction, typically ranging from hundreds to thousands of pounds

- Certification: Meets or exceeds ASTM, MIL, and FAA standards

Types of Aircraft Cables and Their Uses

There are two primary types of aircraft cables, categorized by material composition and protective coatings. Selecting the right cable type is essential for optimal performance, safety, and longevity in your specific application. Let’s explore the most common options:

1. Stainless Steel Aircraft Cables

Stainless steel aircraft cables, typically made from 316 or 302/304 alloys, are the gold standard for environments where maximum corrosion resistance, longevity, and strength are required. 316 stainless steel offers superior resistance to saltwater corrosion, making it ideal for marine and coastal environments, while 302/304 is widely used for general aviation, aerospace, and architectural rigging.

- Applications: Flight control cables, safety barriers, marine lifelines, architectural railings, food processing lines, medical devices, and more.

- Benefits: Exceptional durability, minimal maintenance, non-magnetic options, and long service life even in harsh conditions.

2. Galvanized Aircraft Cables

Galvanized aircraft cables are made from steel wires that are hot-dipped in zinc, providing an economical balance of strength and corrosion protection. While offering similar tensile strength to stainless steel, galvanized cables are more cost-effective for general industrial, agricultural, and construction purposes where extreme corrosion resistance is not critical.

- Applications: Winch cables, guy wires, fencing, overhead doors, lifting slings, livestock pens, utility rigging, and general-purpose use.

- Benefits: Cost-effective, readily available, good corrosion resistance in mild environments, and strong load-bearing capabilities.

Aircraft Cable vs. Wire Rope: What’s the Difference?

While aircraft cables are a specific type of wire rope, the distinction lies primarily in their smaller diameters and construction quality. Wire ropes are typically available in diameters no smaller than 1/4 inch, whereas aircraft cables are commonly used in diameters as small as 3/64 inch. Aircraft cables are manufactured to stringent standards, often with higher flexibility and fatigue resistance, making them suitable for critical control, lifting, and safety applications. If you’re unsure whether your project requires aircraft cable or a heavier wire rope, consider the load requirements, diameter constraints, and regulatory standards involved.

Aircraft Cable Applications: Where and How Are They Used?

Aircraft cables are engineered for precision, reliability, and safety. Their adaptability has led to widespread use in both aviation and non-aviation settings. Here are some of the most common and high-value applications:

- Flight control systems: Primary and secondary flight control surfaces (ailerons, elevators, rudders), engine controls, throttle linkages, and brake systems.

- Lifting and rigging: Wire rope slings for hoisting jet engines, airframe sections, and heavy components during manufacturing or overhaul.

- Arresting gear: Deck cables that engage tail hooks to safely halt aircraft on short or carrier-based runways.

- Marine and offshore: Lifelines, guardrails, and mooring lines on ships, yachts, and oil platforms.

- Architectural: Cable railings, balustrades, suspension bridges, and safety barriers in public spaces.

- Agriculture and irrigation: Support cables for greenhouses, trellises, irrigation booms, and fencing.

- Industrial machinery: Conveyor belts, hoists, winches, cranes, and automated systems.

- Security and safety: Restraint cables, fall protection systems, and safety netting installations.

Industry Use Cases: Why Choose Aircraft Cables?

Buyers often search for aircraft cable solutions when they need a combination of high strength, reliable performance, and resistance to environmental stressors. Typical scenarios include:

- Ensuring precise movement and safety in aircraft control systems

- Lifting and securing high-value or heavy equipment in aerospace manufacturing

- Protecting against corrosion in marine or outdoor environments

- Meeting regulatory compliance for safety-critical infrastructure installations

- Creating long-lasting, visually appealing architectural elements

- Reducing maintenance costs with durable, fatigue-resistant cable systems

Maintenance and Inspection of Aircraft Cables

Aircraft cables operate under demanding conditions. Temperature extremes, moisture, vibration, and exposure to corrosive environments can all contribute to wear and degradation. To ensure safety and reliability, routine maintenance and inspection are essential—especially in aviation and safety-critical applications.

Why Is Aircraft Cable Maintenance Important?

- Safety: Compromised cables can lead to catastrophic system failures, especially in flight control or lifting applications.

- Regulatory compliance: Aviation authorities mandate regular inspections and cable replacements to prevent accidents.

- Longevity: Proactive care extends cable life and reduces the risk of unexpected downtime or costly repairs.

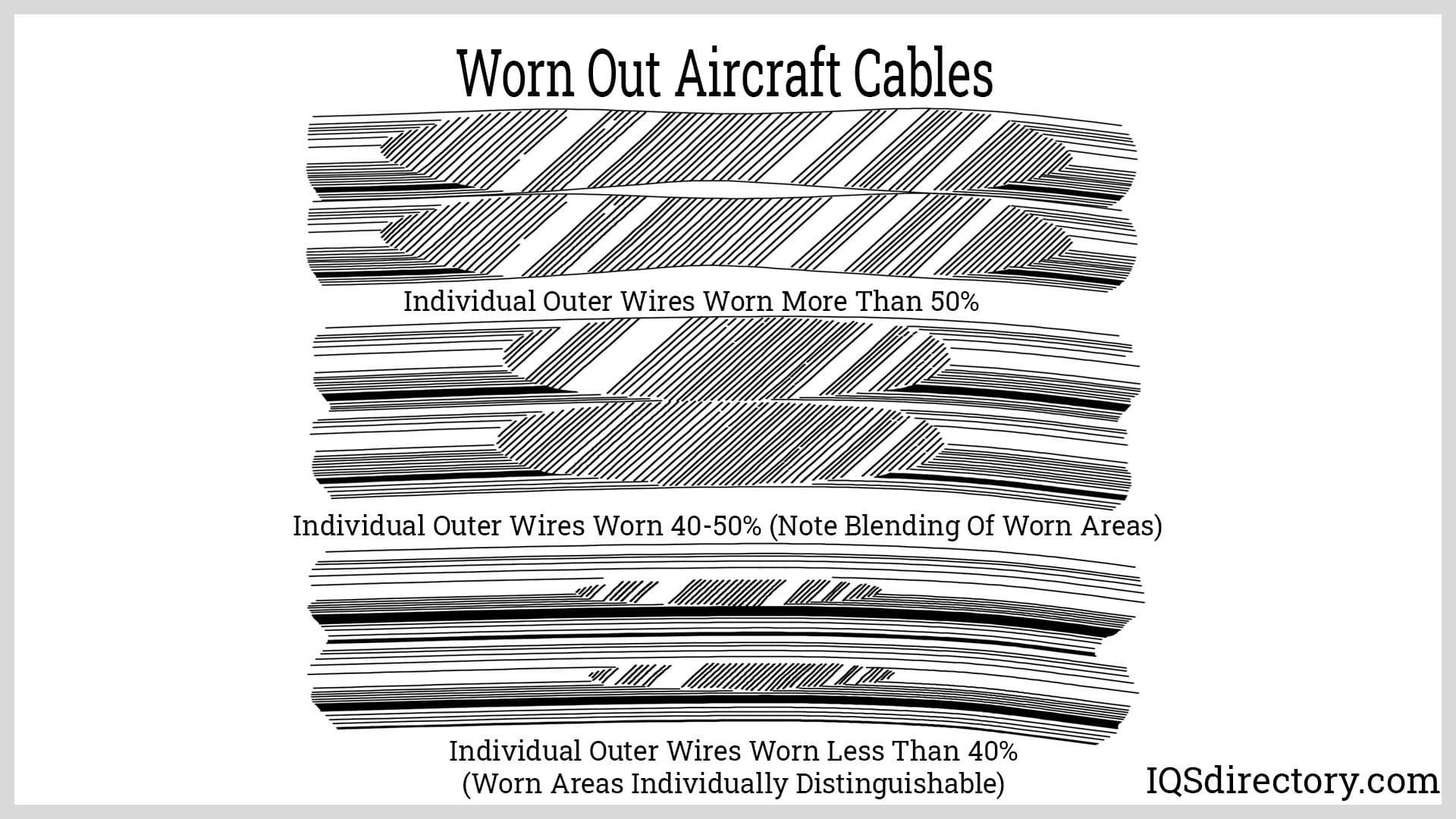

How to Inspect Aircraft Cables

According to FAA and industry guidelines, all control system cables must be inspected regularly—at least every annual or 100-hour interval. Inspections should cover the entire accessible cable length, with particular attention to sections passing over pulleys, through guides, or near swaged fittings.

- Look for damaged, broken, or frayed wire strands, especially in high-fatigue areas.

- Check for signs of corrosion, pitting, or rust—especially on galvanized cables.

- Examine for kinks, distortions, or flattened spots that indicate mechanical stress.

- Inspect swaged fittings and end terminals for cracks, looseness, or movement.

If a single strand is damaged in a critical fatigue region (such as near pulleys, fairleads, or swaged fittings), the entire assembly must be replaced. Internal cable damage is less visible, so in-depth inspection may require removing the cable and flexing it under magnification.

Best Practices for Aircraft Cable Maintenance

- Replace all control cables that have exceeded their intended design life, even if they appear undamaged—typically every 15 years for aviation cables.

- For tailwheel aircraft, replace rudder and tailwheel cables every five years due to higher stress factors.

- Inspect and spin pulleys during maintenance; frozen, worn, or misaligned pulleys can accelerate cable wear.

- Lubricate cables and pulleys according to the manufacturer's guidelines to minimize friction and corrosion.

- Implement an incremental replacement strategy for older aircraft, prioritizing primary control systems first.

How to Select the Right Aircraft Cable for Your Project

Choosing the best aircraft cable depends on a combination of technical requirements, environmental factors, and regulatory considerations. Here are the most important decision factors to evaluate when specifying or purchasing aircraft cable:

- Load capacity: What is the maximum weight or tension the cable must support? Consider dynamic as well as static loads.

- Diameter and construction: Smaller diameters offer greater flexibility, while 7x19 construction provides more flexibility than 7x7.

- Material selection: Stainless steel for maximum corrosion resistance; galvanized for cost-effective general use.

- Environmental exposure: Will the cable encounter salt water, chemicals, extreme temperatures, or high humidity?

- Compliance and certifications: Does your application require meeting MIL, ASTM, or FAA standards?

- End fittings and terminations: Swaged fittings, thimbles, turnbuckles, and custom hardware may be required for secure installation.

- Fatigue and flexibility: Repeated bending, vibration, or movement call for cables with superior fatigue resistance.

- Installation and maintenance: Factor in ease of installation, accessibility for inspection, and long-term maintainability.

Frequently Asked Questions About Aircraft Cables

- What is the difference between 7x7 and 7x19 aircraft cable? 7x7 cables (seven strands of seven wires) offer moderate flexibility and strength, while 7x19 cables (seven strands of nineteen wires) are more flexible and better suited for pulleys or tight bends.

- Are aircraft cables safe for lifting applications? Yes, when selected and installed correctly, aircraft cables are ideal for lifting, hoisting, and rigging—just ensure they meet your project's working load requirements and inspection protocols.

- How often should aircraft cables be replaced? This varies by use and environment, but aviation control cables are typically replaced every 15 years, or sooner if damage or excessive wear is detected.

- Can I use aircraft cable outdoors? Absolutely. Stainless steel cables are best for outdoor, marine, or harsh environments due to their exceptional corrosion resistance. Galvanized cable is suitable for lighter-duty outdoor applications.

- Where can I buy high-quality aircraft cable? Reputable manufacturers and suppliers offer certified aircraft cable in a wide range of specifications—see below for tips on choosing a supplier.

Choosing the Proper Aircraft Cables Manufacturer or Supplier

When it comes to sourcing aircraft cables, the supplier's experience, certification, and quality assurance practices are critical. For safety-critical, mission-essential, or regulatory-compliant applications, always source cables from trusted manufacturers who can provide traceability and documentation for each batch.

To ensure you have the most beneficial outcome when purchasing aircraft cables, it's important to compare several companies. Use our curated list of top Aircraft Cable Manufacturers and Aircraft Cable Suppliers to evaluate at least four or five options. Each supplier profile highlights their industry expertise, product capabilities, and customer service standards. For added convenience, you can request information or quotes directly via our secure contact forms.

- Review each aircraft cable company's website using our patented website previewer to assess their specialties and product range.

- Use our simple RFQ (Request for Quote) form to contact multiple suppliers with your project requirements.

- Request certification documentation and ask about custom solutions, bulk discounts, and lead times.

- Inquire about value-added services such as cable cutting, swaging, end termination, and on-site support.

Looking for bulk pricing or custom cable assemblies? Contact multiple aircraft cable suppliers now for competitive quotes and expert guidance tailored to your application.

Related Products and Accessories

When specifying an aircraft cable system, you may also need compatible hardware to ensure secure, long-lasting performance. Consider the following related products:

- Swaged fittings: For permanent, high-strength connections at cable ends.

- Thimbles and sleeves: To protect cable eyes and prevent wear at attachment points.

- Turnbuckles: For precise tensioning of cables in structural or rigging applications.

- Wire rope clips and clamps: For field-adjustable cable assemblies (not recommended for critical flight control use).

- Cable lubricants and corrosion inhibitors: Extend service life in harsh or outdoor environments.

Explore More on Aircraft Cables

- What are the different types of wire rope slings used in aviation?

- How does galvanized cable compare to stainless steel in marine environments?

- How do I request a custom aircraft cable assembly or bulk order quote?

- What certifications and standards should aircraft cable meet for safety-critical applications?

- What are the best practices for inspecting and maintaining aircraft cables?

Conclusion: Why Aircraft Cables Are Essential for Safety and Performance

Aircraft cables are engineered to deliver unmatched strength, flexibility, and reliability across a wide spectrum of demanding applications. Whether you’re specifying cables for flight controls, industrial hoisting, marine safety, or architectural design, understanding the different types, maintenance requirements, and supplier considerations will help ensure optimal results for your project. Always work with certified manufacturers and follow strict inspection and replacement guidelines to protect your investment and maintain safety standards.

Ready to get started? Request a quote from leading aircraft cable suppliers, or explore our in-depth guides on wire rope, galvanized cable, and wire rope slings to find the perfect solution for your needs.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services