Each filament in steel cable is made of one of a number of iron alloys belonging to the steel family. The most common metal alloy in the world, the steel family includes several variations and combinations of iron and carbon along with other metallic elements to reach specific mechanical and physical properties. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

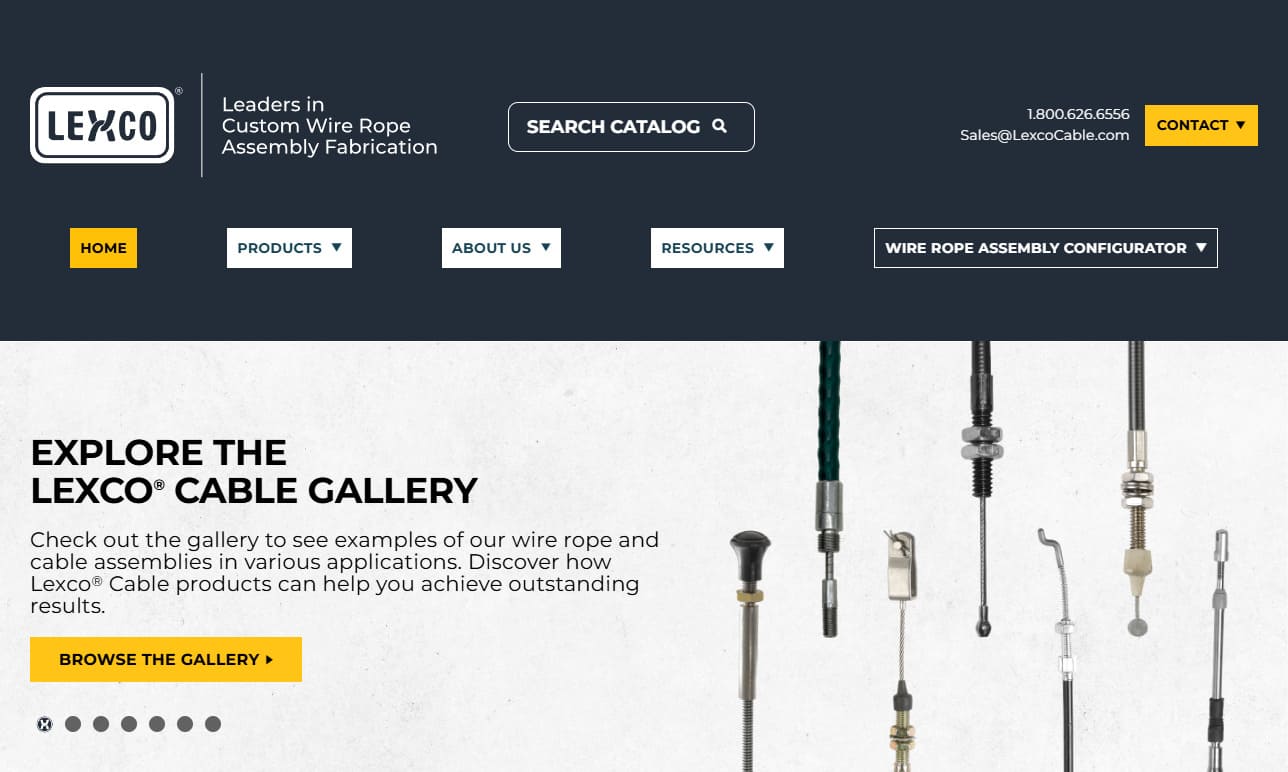

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Steel Cable Manufacturers

Steel is a popular cable composition because of its wear and corrosion resistance as well as its high breaking strength and long product lifespan. Each of these considerations is crucial to steel cable applications.

Often used as safety and control cables, steel wires such as these must be reliable as mechanical failure can lead to costly and even deadly consequences.

Additional specifications include diameter, length, specific composition, resistance to crushing or flattening, and ductility. These should be examined with regard to the intended use of the cable which can range from supportive guy lines, hoist ropes, and cable railings to safety cables and braking mechanisms. Such applications prefer steel cable above other fibrous or synthetic ropes as the multi-strand construction results in the ability to work even in high weight situations while remaining ductile.

Though the configuration can vary, steel cables have the same basic composition. Cold-drawn steel wires known as filaments are the first component. Multiple of these filaments, which have a relatively small diameter, are twisted or braided together to form a grouping referred to as a strand.

The number of filaments per strand is one of the key identifying features of steel cable and can range from two to several dozen.

Strands are then wrapped in a helical pattern around the core. The composition of the core, which may be fibrous even in steel cables, is another element used to identify wire ropes.

Work load limit and finishing may also be used to ensure a given cable is suited to an application.

With steel cables, in particular, it is important to consider the specific alloy in use as steel refers to a grouping of metals with different properties rather than a single element. Stainless steel cables are among the most popular as they offer increased resistance to corrosion and wear even in harsh environments. Galvanized cable, however, is often more cost effective and suitable for most moderate environments. Bright or non-galvanized steel cables are also common.

Each type of steel cable can come as such as a completed assembly with fasteners, fittings and other hardware attached for fray prevention and connectivity.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services