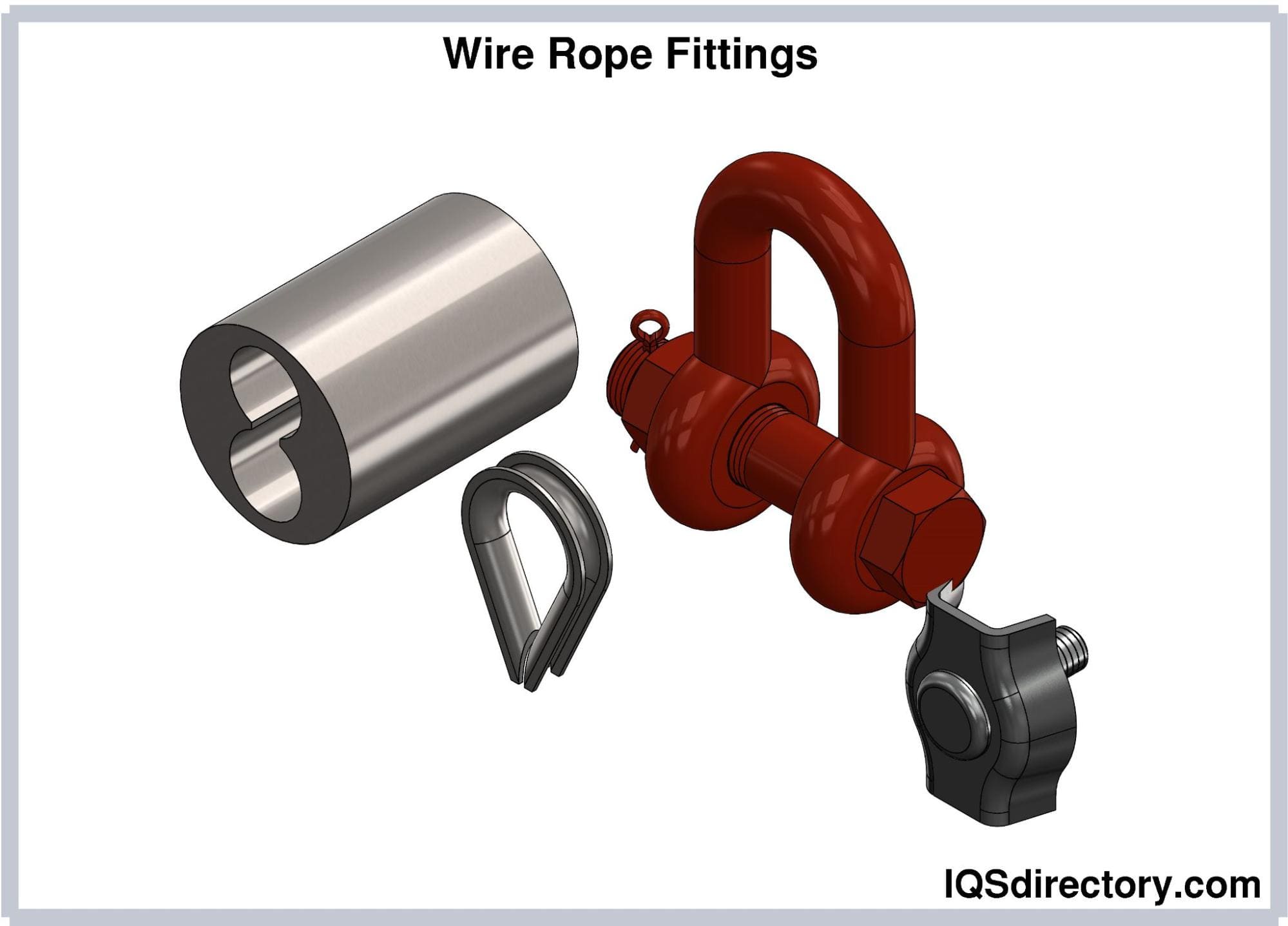

The parts known as wire rope fittings hold the wires’ ends together so they may join to something else. Numerous fitting types are offered in a range of sizes and finishes. Swaged terminations, wire rope clips, poured sockets, and swageless fittings are some of the most popular varieties. These fittings perform various functions in addition to holding the ends of wire rope. For instance, wire rope fittings are used with manual and electric winches to safely rig heavy machinery and cargo. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

At Kennedy Wire Rope & Sling Company, we take pride in being a trusted source for high-performance wire ropes that keep industries moving safely and efficiently. We engineer and supply wire rope solutions that meet the rigorous demands of lifting, rigging, and load-handling applications across construction, marine, energy, and industrial markets.

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

At Zauderer Associates, Inc., we specialize in providing high-quality wire rope solutions designed for durability, safety, and reliability across diverse industries. With extensive experience and technical expertise, we offer a comprehensive range of wire ropes tailored to meet rigorous performance requirements.

More Wire Rope Fitting Manufacturers

Wire rope fittings are essential hardware components used to create secure mechanical terminations and connections for wire rope and control cable assemblies in a wide range of industrial, commercial, and marine applications. In many situations, a wire rope clip, made of nuts and a U-shaped bolt with a grooved base, is used to securely retain the wire rope. To further protect the cable from wear, abrasion, and potential damage, a wire rope sleeve is often paired with the rope clip. The proper assembly of wire rope ends with the right fitting is critical for ensuring the safety, strength, and longevity of machinery and structures operating in diverse environments.

Wire rope and control cable fittings encompass a variety of components—including wire rope clips, sleeves, stud ends, eyes, forks, thimbles, shackles, hooks, swage fittings, and other specialized hardware—used to construct robust mechanical cable assemblies. These fittings are fundamental in motion control, lifting, rigging, hoisting, and machine automation applications, where reliable cable terminations are paramount for operational safety and efficiency. For example, a cable clip is designed to attach network cables to wooden joints and studs, preventing puncture of the protective jacket and avoiding short-circuiting or deformation that could compromise electrical transmission. Careful installation, such as the measured use of a hammer or the employment of cable hangers and trays, helps avoid accidental cable damage and maintains system integrity.

Specifically, a wire rope clip is used to hold and secure wire rope, providing a tight grip that ensures the rope remains properly anchored under load. Wire rope clips typically consist of a U-shaped bolt, a grooved saddle, and two nuts to clamp the rope in place. Additional wire rope fittings—such as chain and anchor shackles, swivel hooks, plate hooks, sockets, and mechanical end terminations—are used to assemble wire rope ends, facilitating connections to other equipment or structures. The use of a wire sleeve with a rope clip is crucial for minimizing friction, reducing wear, and extending the service life of the cable.

Types of Wire Rope Fittings and Accessories

Choosing the right wire rope fitting is essential for ensuring the safety, reliability, and performance of your cable assembly. There are many types of wire rope fittings available to accommodate different load requirements, environmental challenges, and connection needs:

Clevis (Fork, Jaw) Fittings

Clevis fittings, also known as fork or jaw fittings, are socket-style terminations manufactured in a range of finishes, including stainless steel, galvanized steel, and zinc-plated steel. They are available in both forged and machined series to meet various strength and durability requirements. Clevis fittings are widely used in applications such as heavy-duty lifting equipment, crane rigging, suspension bridges, and marine rigging, offering a secure and adjustable connection point for wire ropes.

Marine Eye Fittings

Marine eye fittings are designed to withstand harsh, corrosive marine environments. Available in configurations such as oval eyes, towing eyes, and both forged and machined variants, these fittings are often made from high-grade stainless steel, zinc-coated, or hot-dip galvanized steel. Their corrosion resistance makes them ideal for sailboat rigging, mooring lines, architectural cable railings, and offshore oil and gas applications. Protective coatings are crucial for preventing rust and degradation due to saltwater exposure, ensuring long-term reliability.

Drum Sockets and Coupling Fittings

Drum sockets are used to securely terminate the end of a wire rope on a drum, such as those found in winching or hoisting systems. These sockets are produced in various metals—zinc-plated, galvanized, or self-colored steel—to suit application-specific requirements. Coupling fittings connect two wire rope ends together, allowing for easy extension or replacement of cable segments in the field.

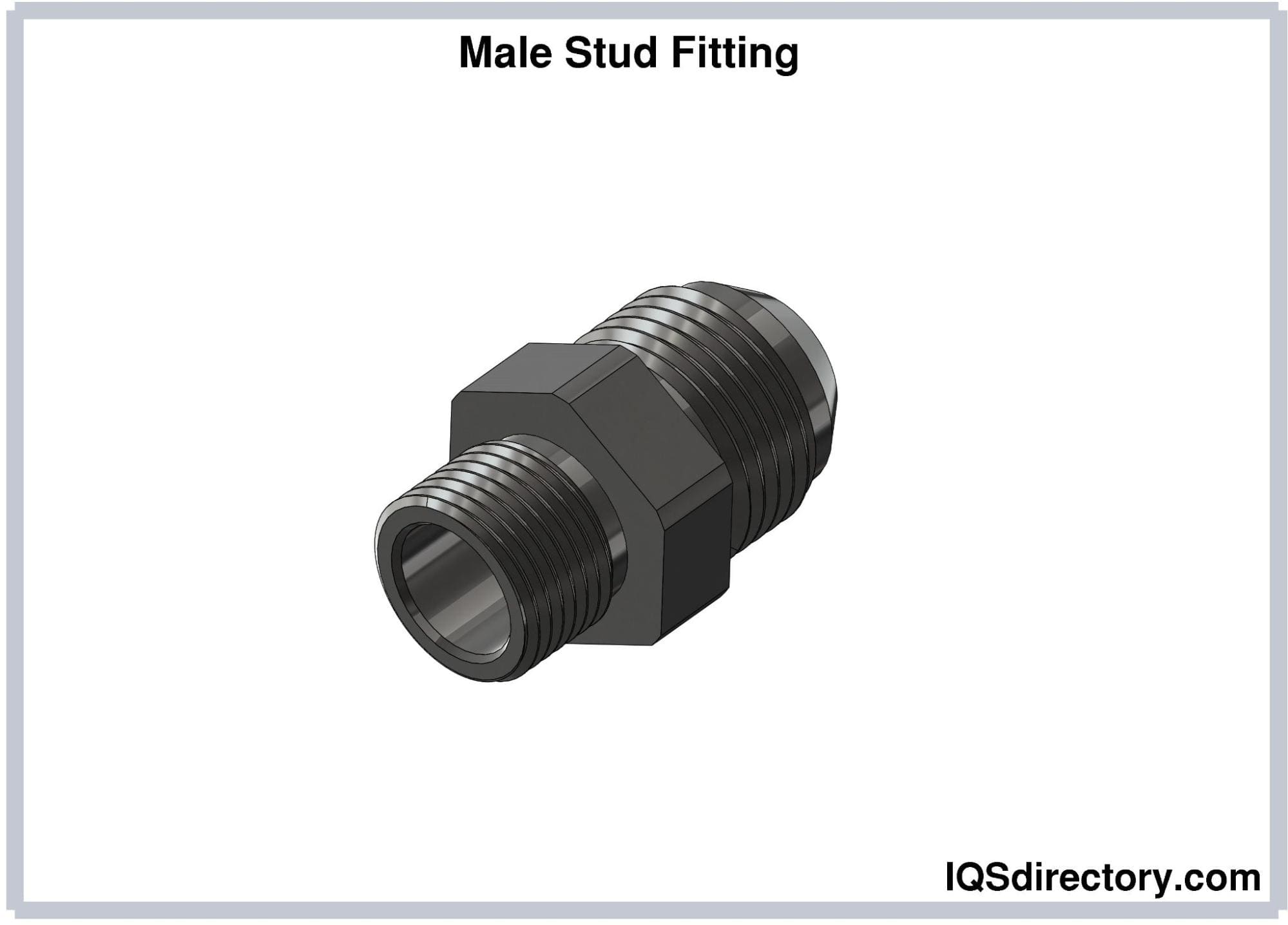

Stud Fittings

Stud fittings—available in coarse or fine threads and fabricated from stainless, zinc-plated, galvanized, or plain steel—are threaded end terminations used to attach wire rope to structural components or to work in conjunction with a turnbuckle for tensioning. Stud fittings are essential in architectural cable railings, tension structures, and applications where controlled cable tension and secure anchoring are required. They also prevent pipe ends from loosening, which can avert fluid leaks in piping systems.

Turnbuckles

Turnbuckles are adjustable fittings that connect two threaded stud ends or other terminations and allow for precise tensioning of wire rope or cable assemblies. By rotating the central body, users can increase or decrease cable tension to remove slack or maintain structural integrity. Turnbuckles are indispensable in rigging, fencing, suspension bridges, commercial construction, and marine applications, where controlled tension is critical for safety and stability.

Swivel Hooks, Swivel Eye Hooks, and Grab Hook Fittings

Swivel hooks and swivel eye hooks are designed to connect two lines or cables, allowing each to rotate independently and prevent twisting under load. Grab hooks are used to securely grab onto chain links or anchor points, providing a strong and reliable connection. These hooks are commonly found in lifting slings, transport tie-downs, towing, and industrial rigging systems.

Lifeline Fittings

Lifeline fittings are specialized components used primarily in military, marine, and industrial safety systems. Their main purpose is to prevent personnel and equipment from falling overboard on ships or off elevated platforms. Lifeline fittings come in diverse styles, including closed-body turnbuckles with sister hooks, clevis fittings, and various quick-release mechanisms for rapid deployment. They are also used in fall-protection systems, safety railings, and restricted-access barriers.

Assembly Kits

Wire rope assembly kits are packaged solutions that include all necessary fittings, plug drivers, and assembly blocks for installing or repairing wire rope terminations. These kits simplify field installation, ensure proper assembly, and help maintain cable system integrity. Commonly available for a variety of cable diameters, assembly kits are ideal for contractors, maintenance teams, and DIY users seeking a reliable solution for cable management and installation.

Replacement Sleeves and Wire Rope Plugs

Replacement sleeves and wire rope plugs are vital for maintaining cable assemblies, allowing users to replace worn or damaged components without the need for complete system overhaul. Sleeves are used to reinforce the cable at termination points, while plugs secure the end of the cable within a fitting. These accessories are available in multiple sizes and configurations to fit a wide range of wire rope constructions.

Wire Rope Fittings: Shapes, Sizes, and Material Options

Wire rope and control cable fittings come in a broad array of shapes, sizes, and material grades to accommodate the diverse requirements of modern industries. Selecting the proper size and material is crucial for ensuring the strength, durability, and safety of the cable assembly.

- Diameter and Sizing: Wire rope clips, for example, are sized to fit specific cable diameters—such as 6.35 mm (0.25 inches)—in accordance with standards like TIA/EIA 568-B.2. Choosing the correct diameter is important for ensuring proper grip and load capacity.

- Product Identification: Each wire rope fitting should feature a unique product identification code (PIC) for material tracking and quality assurance. This helps with compliance, traceability, and maintenance over the product’s lifecycle.

- Corrosion Resistance: Many wire rope fittings, especially those used in outdoor or marine environments, are galvanized or made from stainless steel to prevent rust and corrosion. Features like a red U-bolt on wire rope clips aid in quick identification and safety checks.

- Wire Sleeves: Wire sleeves are available in various sizes to match the cable diameter and construction. The number of strands in the rope, as well as the intended application, will determine the appropriate sleeve and fitting combination.

Manufacturers design wire rope and control cable fittings to meet rigorous industrial standards, ensuring compatibility with a wide range of applications and compliance with organizations such as the American Iron and Steel Institute (AISI), Telecommunications Industry Association (TIA), and the Electronic Industries Alliance (EIA).

Common Applications of Wire Rope Fittings

Wire rope and control cable fittings play a pivotal role in a multitude of industries, supporting both commercial and industrial activities. The versatility and reliability of these fittings make them the preferred choice for any application that demands strong, secure, and adjustable cable connections. Typical industries and use cases include:

- Architecture and Engineering: Used in suspension bridges, cable railings, tension structures, and architectural facades for both functional and aesthetic purposes.

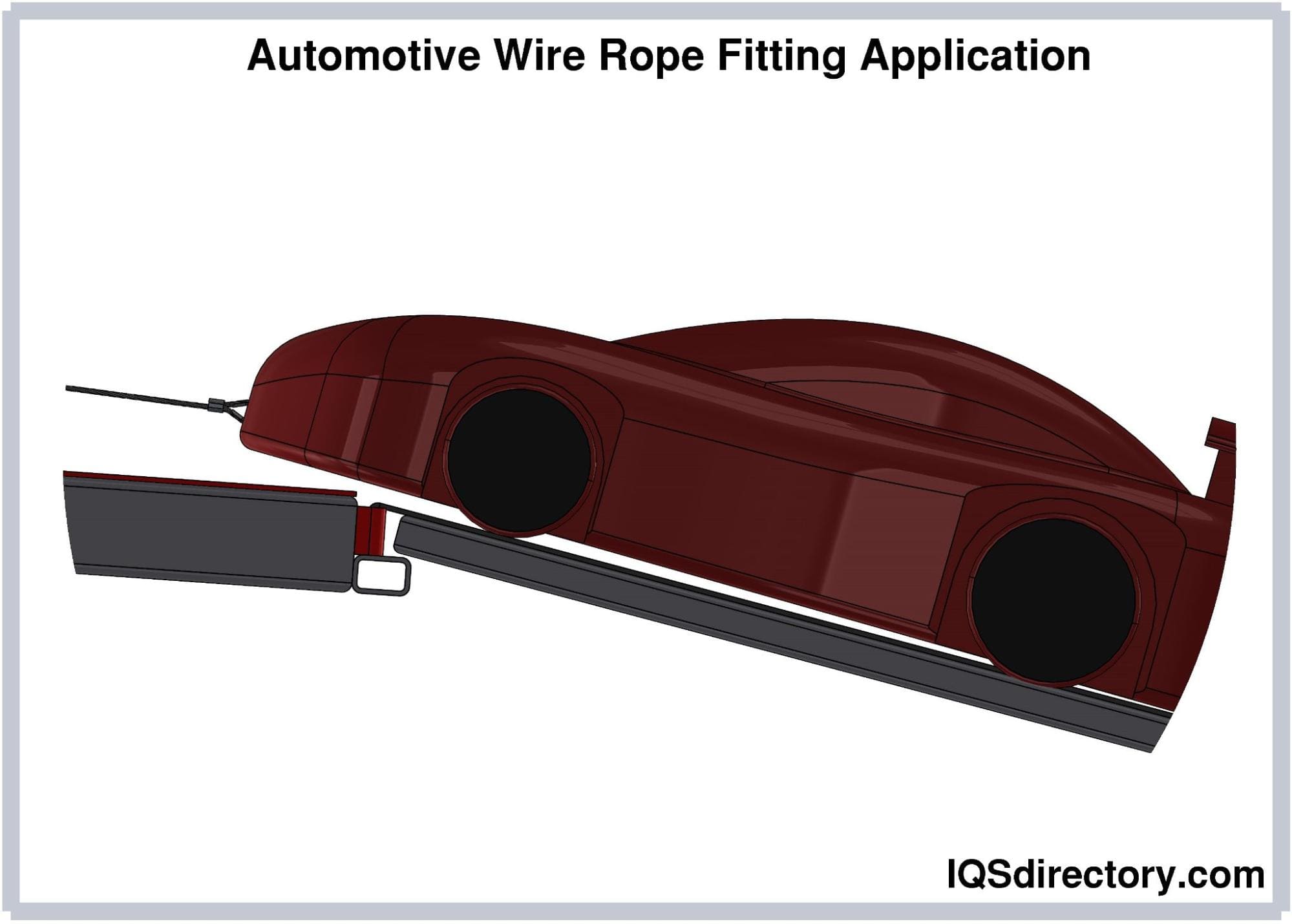

- Automotive: Employed in throttle cables, brake cables, gear shifters, and vehicle hoists to ensure optimal performance and safety.

- Construction: Integral to lifting and rigging systems, scaffolding supports, hoists, cranes, and temporary structural supports.

- Energy and Power: Applied in transmission line supports, wind turbine maintenance, and oil and gas rigging operations.

- Military: Used in shipboard lifelines, military vehicle cable assemblies, and specialized lifting and securing equipment.

- Transportation: Essential for securing cargo, elevator cables, railway tensioners, and cable-stayed bridges.

Heavy-duty applications such as lifting, hoisting, supporting, and securing machinery or structural components frequently rely on high-performance wire rope fittings. In addition to industrial uses, these fittings are commonly found in non-industrial settings, such as:

- Marine and Boating: Sailboat rigging, mooring lines, ship railings, and lifeline systems for safety at sea.

- Sports Equipment: Gym cable systems, climbing gyms, zip lines, and cable-supported sports nets.

- Public Infrastructure: Walkways, pedestrian bridges, cable railings, and tensioned art installations.

Benefits of Using High-Quality Wire Rope Fittings

Investing in premium wire rope fittings offers numerous advantages, including:

- Enhanced Safety: Properly engineered and installed fittings minimize the risk of cable slippage, structural failure, or equipment damage, ensuring workplace safety and compliance with industry regulations.

- Long-Term Durability: Corrosion-resistant materials and robust construction methods extend the service life of wire rope assemblies, reducing maintenance costs and downtime.

- High Load Capacity: Precision-manufactured fittings are rated for specific load limits, providing confidence in critical lifting, towing, or tensioning applications.

- Versatility: A wide selection of fitting types and sizes enables custom cable assemblies for virtually any project, from industrial cranes to architectural railings.

- Ease of Installation: Many modern fittings are designed for quick and straightforward installation, making field assembly and maintenance more efficient.

Looking to learn more about how to select the right wire rope fitting for your application? What are the best practices for installing wire rope clips and sleeves? Explore our in-depth guides or reach out to our technical support team for personalized recommendations.

How to Select the Right Wire Rope Fitting for Your Needs

Selecting the optimal wire rope fitting involves evaluating several key factors:

- Intended Application: Identify whether the fitting is for lifting, securing, tensioning, marine use, or another specific purpose, as each scenario may require a different type of fitting or material.

- Load Requirements: Calculate the maximum expected load and choose fittings rated to exceed this value, incorporating an appropriate safety factor as recommended by industry standards.

- Environmental Conditions: Consider exposure to moisture, chemicals, saltwater, or extreme temperatures. Stainless steel and galvanized fittings offer superior corrosion resistance for harsh environments.

- Cable Compatibility: Ensure the fitting matches the diameter, construction, and flexibility of your chosen wire rope or control cable.

- Ease of Assembly and Maintenance: Some fittings may require specialized tools for swaging or crimping, while others offer field-installable solutions for rapid deployment or replacement.

- Compliance and Certification: Look for fittings manufactured to recognized standards (such as AISI, TIA, EIA, or ISO) for guaranteed quality and traceability.

When searching for wire rope fittings, consider questions such as: Which type of fitting is best for marine environments? How do I calculate the correct size and number of wire rope clips for my application? What are the recommended installation procedures to ensure safety and compliance? Addressing these factors will help you make an informed decision and maximize the reliability of your cable assembly.

Expert Tips for Installation and Maintenance

Proper installation is critical for the safe and long-lasting performance of wire rope fittings. Here are some expert tips and best practices:

- Always use the correct number and size of wire rope clips for each assembly. Follow manufacturer guidelines and industry standards for clip spacing and torque.

- When using wire rope sleeves, ensure they are crimped or swaged with the appropriate tool to achieve maximum holding strength.

- Regularly inspect all fittings for signs of wear, corrosion, deformation, or loosening, and replace any compromised components immediately.

- Apply anti-seize lubricant to threaded fittings in corrosive environments to aid in future disassembly and prevent galling.

- Document all installations with part numbers and inspection dates to maintain compliance and facilitate scheduled maintenance.

Curious about how to troubleshoot common wire rope fitting issues? What are the warning signs of fitting failure? Visit our troubleshooting guide or contact our technical experts for support.

Choosing the Right Wire Rope Fittings Supplier

To achieve the most productive outcome when purchasing wire rope fittings, it's essential to partner with a reputable and experienced supplier. Here are steps you can take to ensure you select the best provider for your needs:

- Compare Multiple Suppliers: Evaluate at least four wire rope fittings suppliers using our comprehensive list of vetted companies. Review each supplier’s business profile to understand their strengths, capabilities, and areas of expertise.

- Request Detailed Quotes: Use our simple RFQ (Request for Quote) form to contact multiple manufacturers simultaneously. Be sure to specify your technical requirements, quantities, material preferences, and delivery timelines.

- Review Certifications and Quality Assurance: Select suppliers who adhere to recognized industry standards and maintain rigorous quality control processes.

- Preview Company Websites: Take advantage of our proprietary website previewer to quickly assess each supplier’s specializations, product range, and support resources.

- Direct Communication: Use the contact forms to ask technical questions, request product samples, or arrange site visits to assess manufacturing capabilities firsthand.

Ready to source high-quality wire rope fittings for your next project? How do you choose between stainless steel, galvanized, or zinc-plated fittings? What are the lead times and shipping options? Reach out to our recommended suppliers today for personalized assistance and competitive pricing.

Frequently Asked Questions About Wire Rope Fittings

- What is the difference between swaged and mechanically attached fittings?

Swaged fittings are permanently attached by compressing or crimping the fitting onto the cable with a hydraulic press, resulting in a strong, tamper-proof termination. Mechanically attached fittings typically use bolts, nuts, or wedges and can be installed in the field without specialized equipment, offering greater adjustability and ease of maintenance. - How do I determine the correct number of wire rope clips for a safe assembly?

The required number of clips depends on the cable diameter and application. Industry standards and manufacturer recommendations should always be followed to ensure safety and load capacity. - Can wire rope fittings be reused after disassembly?

Most wire rope clips and some mechanical fittings can be reused if they are free of wear, deformation, or corrosion. Swaged and crimped fittings are generally not reusable and should be replaced if removed. - What maintenance is required for wire rope fittings?

Regular inspections, lubrication of moving or threaded parts, and prompt replacement of worn or damaged components are essential for maintaining system reliability and safety.

Still have questions about wire rope and control cable fittings? Looking for recommendations on the best fittings for your specific industry or project? Explore our resource library, or contact our experts for tailored advice and product selection assistance.

Conclusion

Wire rope fittings are indispensable in countless applications, from heavy-duty lifting and industrial rigging to architectural design and marine safety systems. By understanding the various types, materials, and use cases, and by following best practices for selection, installation, and maintenance, you can ensure the safety, performance, and longevity of your cable assemblies. For the best results, always partner with experienced wire rope fittings suppliers who offer high-quality products, technical support, and responsive service. Start your search today and discover the ideal fittings for your unique application needs.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services